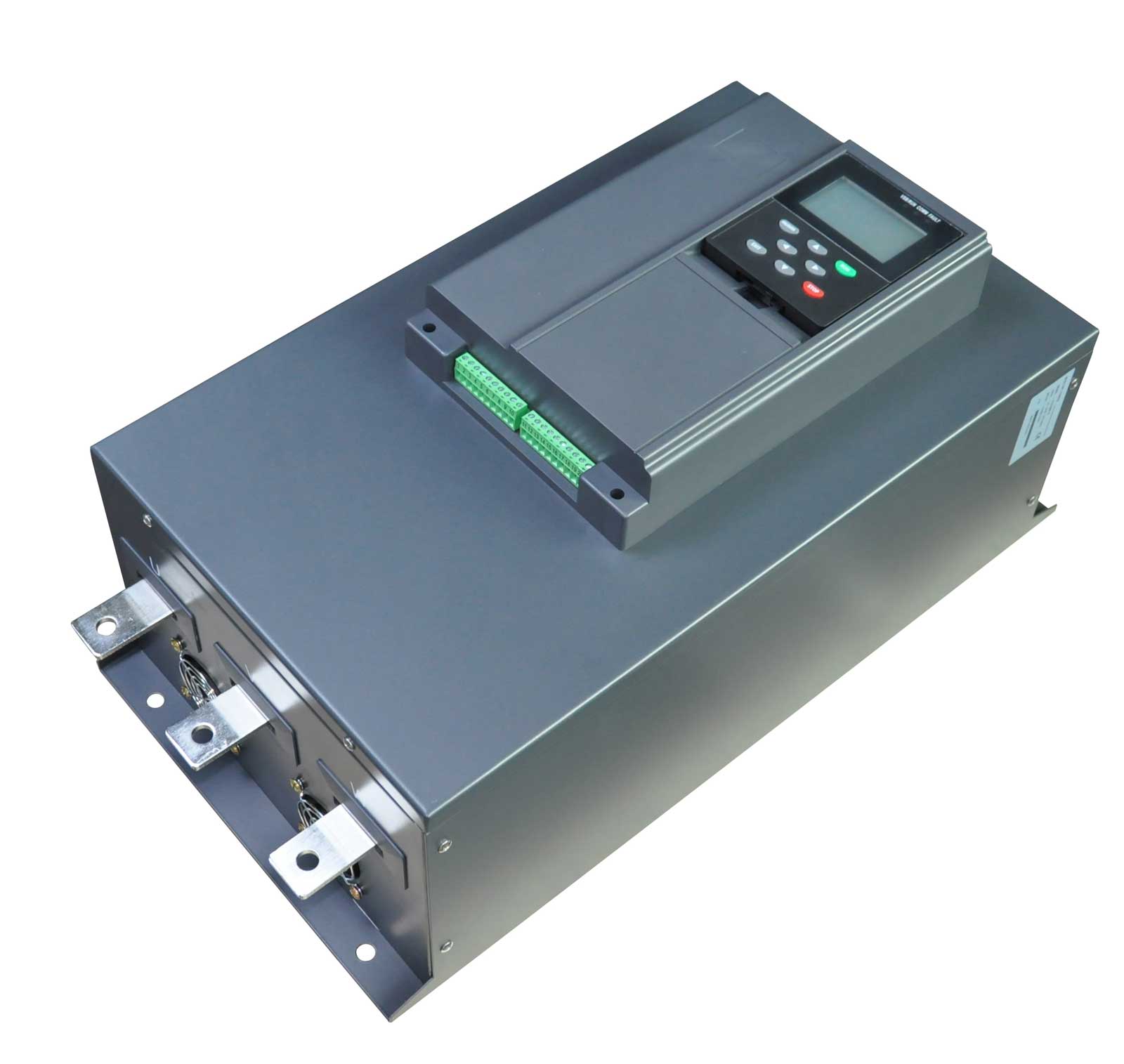

Customization of high-voltage frequency conversion cabinet

Provide users with comprehensive high-voltage (asynchronous, synchronous) AC motor soft start, speed regulation, and intelligent control solutions, widely used in power generation, petrochemical, mining, metallurgy, cement, municipal, light industry and other industries, and have won high praise from users.

Power range

400~25000kVA

Input voltage

6kV 3 phase to 3 phase

10kV 3 phase to 3 phase

Product Overview

Application scope

-

Automation production equipment such as textiles

-

Paper Making

-

Sand Making

-

Machine Tools

-

Packaging

-

Food

-

Fans

-

Pumps

- Motor control strategy: asynchronous machine universal, asynchronous machine vector, asynchronous machine open-loop vector, synchronous machine universal, synchronous machine vector, synchronous machine open-loop vector, etc

- Magnetic flux closed-loop vector control technology: Based on the mathematical model of the motor, the magnetic flux of the motor is closed-loop controlled

- Unit bypass technology: Optional bypass methods, including mechanical bypass and electronic bypass

- Neutral drift technology: When a power unit malfunctions, only the faulty unit is bypassed and the output voltage neutral point is adjusted to improve the voltage output capability

- Output voltage self adjustment function: When the input voltage fluctuates (-10%~+5%), the frequency converter has the rated voltage output ability

- Torque enhancement function: increases the load capacity of the motor during startup and low-frequency operation

- Speed start function: When the motor is rotating, the frequency converter with the motor starts smoothly to reduce the impact on the power grid

- Instantaneous power outage function: When an instantaneous power outage occurs in the power grid, the frequency converter operates continuously and stably

- High voltage power loss self start function: After switching to the power grid or recovering from a short-term power loss, the frequency converter automatically restarts

- Synchronous switching function (optional synchronous switching cabinet): achieve undisturbed switching between power frequency operation and variable frequency operation of the motor, reducing the impact on electrical equipment and the power grid

- Master slave control function: dual or multi machine linkage operation of frequency converter

- Process PID control function

- Upper communication function

Technical Specifications

| project | parameter |

| Rated capacity of frequency converter | 400-25000kVA |

| Rated voltage | 2.3kV~11kV (-20%~+5%) (out of range, special instructions required) |

| Rated frequency | 50Hz/60Hz (-10%~+10%) |

| Control power supply | 380VAC, 30kVA |

| Rated input power factor | ≥ 0.96 |

| Overall efficiency | >96% |

| Output frequency range | 0~80Hz |

| Speed accuracy | ± 0.5% (open loop vector) ± 0.1% (closed loop vector) |

| Instantaneous overcurrent protection | 150% (customizable according to user requirements) |

| Overload capacity | 120% load, 120s |

| Torque limit | 10%~150% |

| Analog input | 3-way 4-20mA/excitation feedback 4-20mA (customizable) |

| Analog output | 4-way 4-20mA |

| Upper communication | Isolated RS485 interface, ModBus, RTU (optional: Profibus, DP, industrial Ethernet protocol) |

| Acceleration and deceleration time | 5 seconds to 6000 seconds (load dependent) |

| Switching input and output | 14 inputs and 22 outputs (8 outputs can be defined) |

| Operating ambient temperature | -5~+45 ℃ |

| Storage/transportation temperature | -25~+55 ℃ |

| Cooling method | Forced Air Cooling (AF)/Water Cooling (WF)/Air Water Cooling (AFWF) |

| Environmental humidity | < 95%, no condensation ※ |

| Installation altitude | ≤ 1000 meters, above 1000 meters above sea level, derate by 1% for every 100 meters increase in operation |

| dust | Non conductive and non corrosive,<6.5mg/dm3 |

| Protection level | IP30 |

| Cabinet color | RAL 7035 (or customized according to the color code provided by the user) |

Download

Download

Contact Us

Contact Us